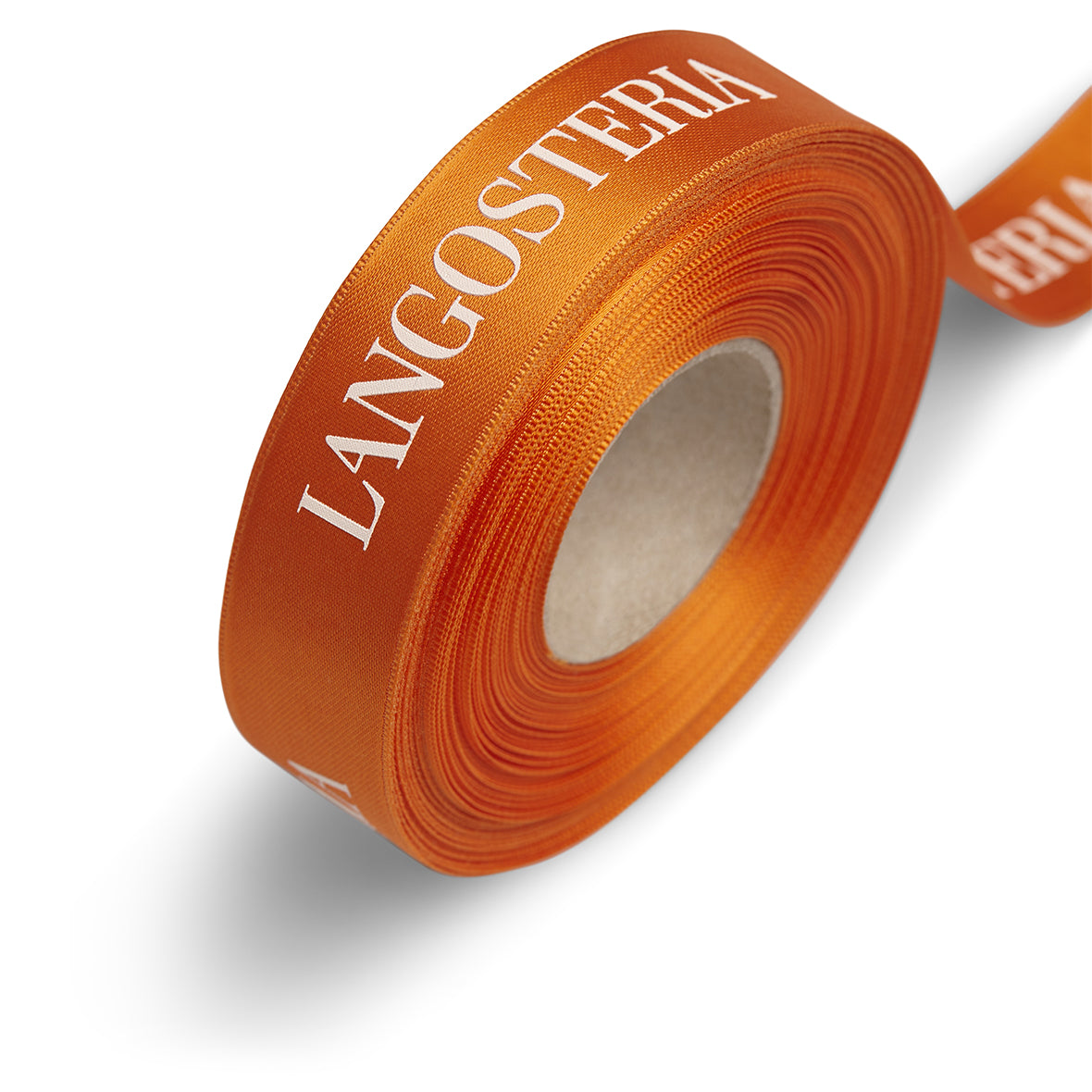

The world of packaging is constantly evolving, and customized ribbons have become an essential component for creating unique packages. However, behind these simple ribbons lies a world of cutting-edge printing technologies that enable the creation of extraordinary designs. Below we delve into the main printing technologies for the production of customized ribbons .

EMBOSSED SILKSCREEN PRINT

Screen printing is one of the oldest printing methods that requires the creation of a screen printing frame. The printing process involves placing the frame on the printing machine as well as the ribbon fabric which will need to be customized. Subsequently, the ink is added to the surface of the frame and a spatula moving back and forth pulls it along the entire length, distributing the color evenly. In doing so, the ink is pushed through the open areas of the frame, imprinting the design on the surface of the underlying ribbon. It is important to note that screen printing is a monochrome technique and one of the advantages is the possibility of choosing from a wide variety of inks, allowing you to obtain unique effects and decorations of great value. Screen printing also offers control over the thickness of the ink deposited, opening up further creative opportunities.

SUBLIMATIC PRINTING

The sublimation process is the transformation that the inks undergo when, coming into contact with heat, they transform into gas (sublimate) and join in a stable manner to the surface of the tape. Sublimation is achieved using inkjet printers equipped with sublimation inks, using special sublimation paper. Subsequently, the ink received from the paper is transferred to the surface of the ribbon using a special calender. The final result allows you to have a tape with graphics of great visual impact without any relief and washable.

HOT STAMPING

Hot stamping is a printing process that involves the use of heat to transfer synthetic or metallic foils onto custom ribbon. This process involves the use of a cliché, usually made of zinc or bronze, which is engraved with the desired graphics, creating a raised surface that allows the controlled transfer of the foil. During execution, the cliché is positioned and heated on the plate located near the ribbon, and through the combination of pressure and temperature, the foil is imprinted on the surface.

Hot stamping offers a wide range of possibilities, including luster and metallization effects.